We’ve previously discussed the importance of carbon assessments in shaping a more sustainable built environment. Building on that foundation, Whole Life Carbon Assessment (WLCA) takes this understanding a step further. It provides a comprehensive framework for evaluating and reducing emissions across a building’s entire lifecycle from raw material extraction through to end of life.

Unlike traditional approaches that focus solely on operational energy use, WLCA captures the complete carbon picture. It enables more informed decisions that balance environmental impact, cost, and performance. Guided by international standards such as BS EN 15978, this approach helps translate sustainability ambitions into measurable action.

Understanding the Lifecycle Stages of Whole Life Carbon Assessment

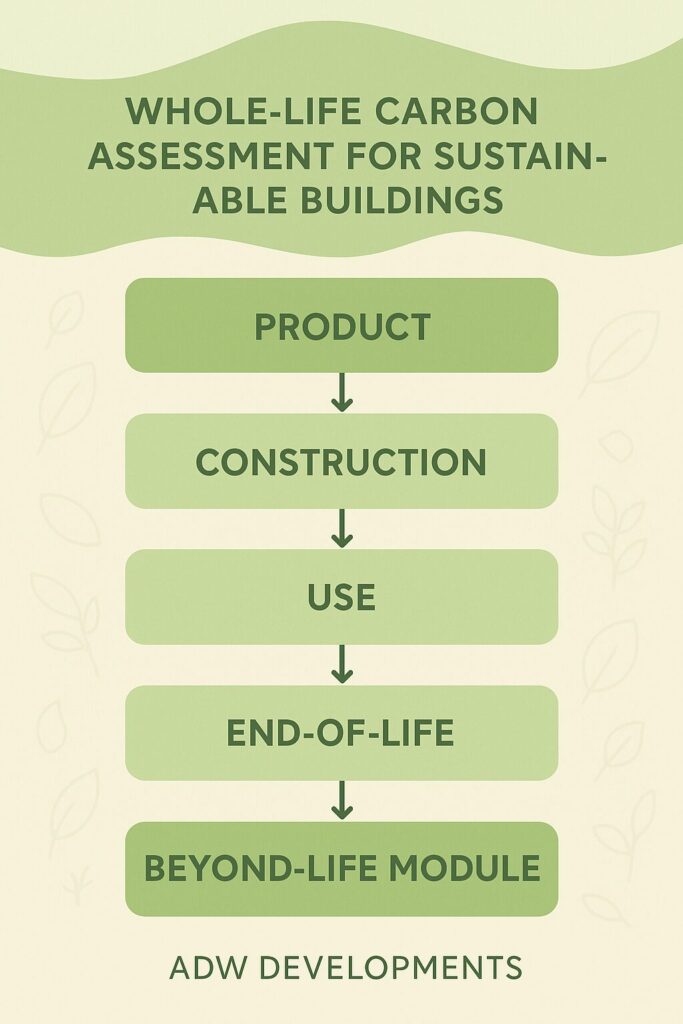

Whole Life Carbon Assessment, as standardised in BS EN 15978, divides a building’s lifecycle into distinct modules. This systematic structure ensures emissions are evaluated comprehensively across every stage, providing a transparent view of a building’s total carbon impact. These modules are grouped into four primary stages, plus an additional stage that captures benefits and burdens beyond the immediate lifecycle.

1. Product Stage (A1–A3)

This initial stage considers emissions generated before construction begins, encompassing the entire process of material creation:

- A1: Raw Material Supply – Emissions from extracting and processing raw materials, such as quarrying aggregates, mining metals, or harvesting timber, including energy use and land impacts.

- A2: Transport – Emissions from transporting these raw materials to manufacturing facilities.

- A3: Manufacturing – Emissions from producing construction materials and components, including energy-intensive activities such as smelting, firing, or chemical processing (e.g. for cement, glass, or insulation).

Understanding material carbon intensity at this stage is crucial, as it determines the embodied carbon locked into a building from the outset.

2. Construction Process Stage (A4–A5)

Once materials are produced, emissions arise from construction activities themselves:

- A4: Transport to Site – Emissions from delivering construction products to site; these can be reduced through efficient logistics and local sourcing.

- A5: Construction/Installation Process – Emissions from on-site activities such as machinery use, energy consumption, and waste generation.

Efficient site management, waste minimisation, and low-carbon construction techniques are key to reducing emissions at this stage.

3. Use Stage (B1–B7)

The use stage, typically the longest in a building’s life, covers emissions generated during occupancy and operation:

- B1: Use – Emissions from general building use not covered by other modules.

- B2–B3: Maintenance and Repair – Emissions from routine maintenance and essential repairs.

- B4–B5: Replacement and Refurbishment – Emissions from replacing or refurbishing components during the building’s life.

- B6: Operational Energy Use – Often the largest contributor to lifetime carbon emissions, including energy used for heating, cooling, ventilation, and lighting.

- B7: Operational Water Use – Emissions linked to water treatment, pumping, and heating.

Reducing operational energy and water use through design optimisation and renewable energy integration is fundamental to achieving net-zero performance.

4. End-of-Life Stage (C1–C4)

At the end of a building’s service life, emissions arise from deconstruction and waste management:

- C1: Deconstruction/Demolition – Emissions from dismantling or demolishing the structure.

- C2: Transport – Emissions from moving waste materials to processing or disposal facilities.

- C3: Waste Processing – Emissions from activities such as sorting, crushing, or incineration.

- C4: Disposal – Emissions from landfill or other final disposal processes.

Applying circular economy principles, such as designing for disassembly and maximising reuse or recycling, can significantly reduce emissions at this stage.

5. Beyond the Building Life Cycle (Module D)

Module D captures potential benefits or burdens arising beyond the building’s lifecycle, including:

- Reuse, Recycling, and Energy Recovery – Credits are applied for materials reused or recycled into new products, or for energy recovered from waste. For example, recycling steel reduces the need for new virgin production, offsetting future emissions.

Module D underscores the importance of material recovery and closed-loop systems, encouraging a shift towards truly circular construction practices.

FAQs

What is Whole Life Carbon Assessment (WLCA)?

WLCA is a comprehensive framework for assessing and reducing GHG emissions across a building’s entire lifecycle—from raw material extraction to end-of-life—covering both embodied and operational carbon.

What is the primary standard for WLCA?

The international standard BS EN 15978 defines the methodology for assessing environmental performance and carbon impacts across all building lifecycle stages.

What is the difference between embodied carbon and operational carbon?

Embodied carbon comes from material production and construction processes, while operational carbon arises during the building’s use, primarily through energy consumption.

Why is Module D important?

Module D captures the benefits or burdens of reuse, recycling, and energy recovery beyond the building’s life, promoting circular economy principles and reducing overall emissions.

How does WLCA support net-zero carbon goals?

WLCA provides a holistic view of a building’s emissions, enabling informed choices that minimise carbon at every stage—from design and construction to operation and end-of-life.

The Value of Whole Life Carbon Assessment

To sum it up, WLCA offers a clear view of a building’s total carbon footprint, helping stakeholders identify emission hotspots and prioritise low-carbon solutions. It informs material selection, construction practices, sustainable operations, and circular economy strategies such as reuse and recycling.

Collaboration between architects, engineers, contractors, and sustainability professionals, supported by digital tools integrating material, energy, and carbon data, ensures WLCA drives effective, measurable outcomes. Applied well, it becomes a cornerstone of sustainable design and a key enabler of net-zero carbon goals, promoting smarter, resilient, and low-carbon buildings.

Get started:

🔍 Learn: Explore resources on WLCA and sustainable construction at WholeLifeCarbon.com.

🤝 Collaborate: Work with architects, engineers, and sustainability experts to embed WLCA in your projects.

💡 Innovate: Harness digital tools to measure and reduce carbon across every building lifecycle stage.

Contact us today to explore how we can support your journey towards net-zero, resilient, and low-carbon buildings.